PZLHM

Compressed air – Hollow clamping cylinders

"Pneumatic power for delicate actuation."

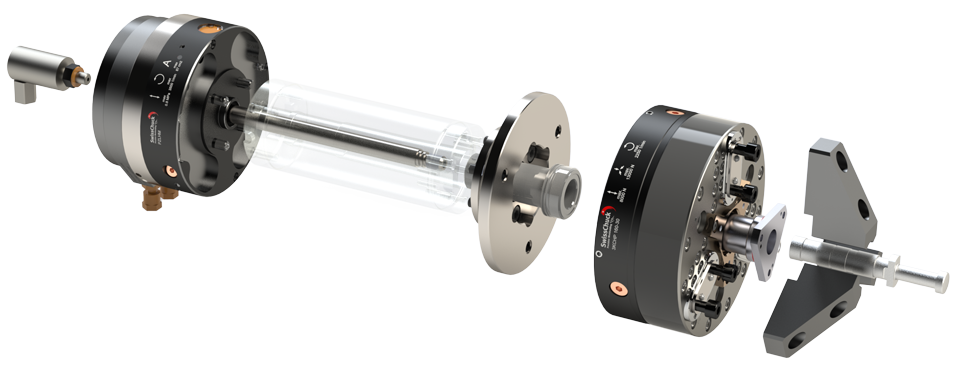

The compressed air hollow cylinders were specially developed as a clamping unit for power clamping devices on machine tools with RPMs up to 8000 min‾¹. Rotating clamping cylinders are attached to the spindle end of a lathe or a grinding machine. They have the task of generating an axial force for the rotating power chucks mounted at the spindle head. This axial force is transmitted via a connecting link, designed as a tube or a drawbar, going through the spindle bore to the respective power chuck used with an adapter.

Downloads

PZLHM Druckluft-Hohlspannzylinder DE

Technical Data

PZLHM

| Item | Outer-ø (mm) | Passage-ø (mm) | Speed (1/min) | F axial max. (daN) | Piston Force (cm2) | Stroke (mm) | Stroke Volume (dm3) | Weight (kg) |

| PZLHM 155 | 155 | 22.5 | 8000 | 612 | 102 | 13.5 | 0.14 | 4.7 |

| PZLHM 180 | 180 | 34.5 | 7500 | 1050 | 175 | 20 | 0.35 | 6.7 |

| PZLHM 200 | 200 | 34.5 | 7500 | 1410 | 235 | 20 | 0.47 | 8.25 |

| PZLHM 200 | 200 | 34.5 | 6000 | 1410 | 235 | 32 | 0.75 | 8.4 |

| PZLHM 220 | 220 | 43 | 6000 | 1740 | 290 | 20 | 0.58 | 10 |

Functions & Fields of Application

- Cylinder with a through bore, for example, for grinding fluids or air-controlled workpiece contact

- Available in varied sizes and different piston surfaces

- Special design for your machine

Advantages

- Compact and lightweight construction

- Double-action clamping cylinder, pneumatic clamping, and releasing

- Adapted for precision chucks

- With safety valves. Clamping is pneumatically safeguarded

Specially designed clamping cylinder for your machine, too!

We are also happy to support you with a specific solution for your machine. Do you need more stroke or even more sensitive clamping? Do not hesitate to contact us - we have already implemented numerous special solutions.

Integrated safety valves for maintaining the clamping pressure!

The safety valve system integrated into the cylinder enables the clamping pressure to be maintained in the event of a hose rupture or a sudden drop in pressure, thereby preventing premature release of the clamped workpiece in the power chuck until the spindle comes to a standstill.

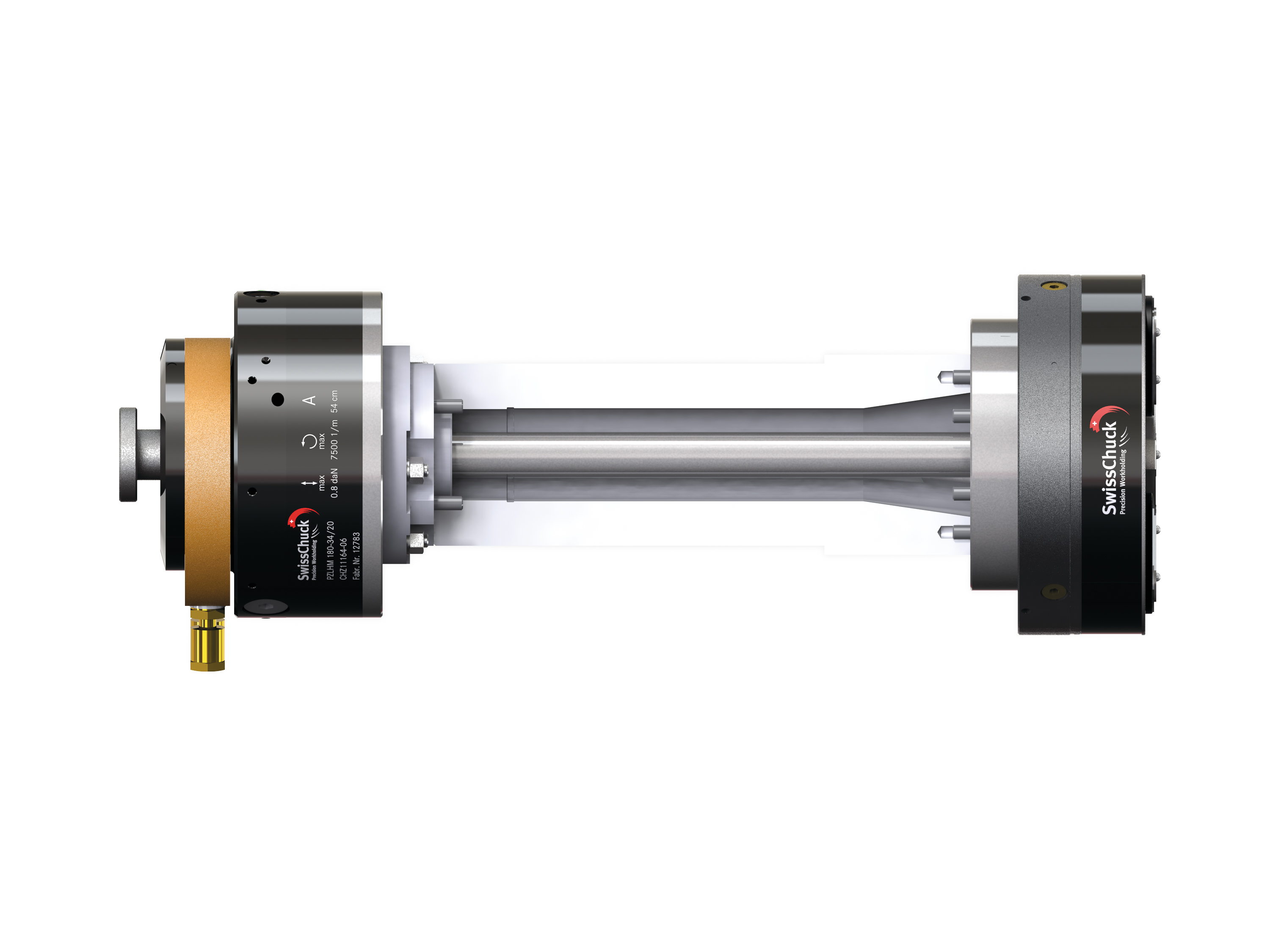

PZLHM 180

All components are fine-tuned and from a single source

- All components are fine-tuned and from a single source:

- Optimal actuation force for the clamping tool

- Necessary clamping stroke for the clamping tool

- All adaption components (drawbars, flanges, etc.)

Magnetic Chuck

With radial or parallel pole pitch

KFHP

Precision power chucks for large workpieces

KCHP / VKCHP

Precision power chuck for cylindrical grinding machines

TGC / FTGC

Tool chucks TGC for the automated production

Triton

Precision power chuck for soft and hard-turning operations

LZK / LZK-S

Multi-blade Collet Chuck LZK-S

![LZK / LZK-S [Translate to English:] Spannzangenfutter LZK-S](/fileadmin/_processed_/3/e/csm_210927_S2_Var_2_LZK-BS_kpl_Schnitt_mit_Spannzange_mit_Werkst%C3%BCck_c8475f7738.jpg)