Triton

Precision power chuck for soft and hard-turning operations

"The precision turning chuck for process-reliable and micrometer precision production."

With Triton®, SwissChuck AG has introduced a modular power chuck range that caters to high-end applications such as turning, hard turning, and grinding. Precision manufacturing and high-quality materials components guarantee a radial runout of less than 5 µm. The precision interfaces between the base and top jaws ensure a fast change-over of the accessory parts and guarantee constant chucking repeatability, eliminating subsequent turning or regrinding of the top jaws. The extended version, Triton® PLUS, additionally features centrifugal force compensation and thus guarantees constant chucking force at high RPM, specifically when dealing with hard turning.

Technical Data

Triton®

| Type | Item | ø Size (mm) | Height (mm) | ø Passage (mm) | Clamping Force (kN) | Speed (1/min) | Stroke per Jaw (mm) | Weight (kg) |

| Triton® 165 | SX1029948-OFA | 165 | 67 | 40 | 12 | 3500 | 2.5 | 8 |

| Triton® PLUS 165 | SX1029948 | 165 | 67 | 40 | 12 | 6000 | 2.5 | 9 |

| Triton® 220 | SX1029929-OFA | 220 | 88 | 60 | 35 | 2700 | 3.5 | 18 |

| Triton® PLUS 220 | SX1029929 | 220 | 88 | 60 | 35 | 4500 | 3.5 | 20 |

| Triton® 290 | SX1024480-OFA | 290 | 117 | 80 | 55 | 2100 | 4.5 | 45 |

| Triton® PLUS 290 | SX1024480 | 290 | 117 | 80 | 55 | 3500 | 4.5 | 48 |

| Triton® 370 | SX1031119-OFA | 370 | 140 | 116 | 80 | 1800 | 5.4 | 85 |

| Triton® PLUS 370 | SX1031119 | 370 | 140 | 116 | 80 | 3000 | 5.4 | 22 |

Function & Fields of Application

- Radial runout ≤ 0.005 mm

- Accuracy of jaw change over ≤ 0.002 mm

- No need for regrinding clamping faces after jaw change-over

- Completely sealed off and low maintenance

- Jaws can be changed between chucks of the same design

- Reinforces jaw interface for high material removal rate

- Offers a wide range of applications; a chuck for turning, hard-turning, and grinding

Advantages

- Sealed, suitable for applications on lathes and grinding machines

- Precision interface between the base and top jaws

- Optional centrifugal force compensation, Triton® PLUS version for high RPM turning operations

- Standard accessories available

- Large through-hole, bar feeding option possible

Changing jaws within micrometer tolerances is made easy!

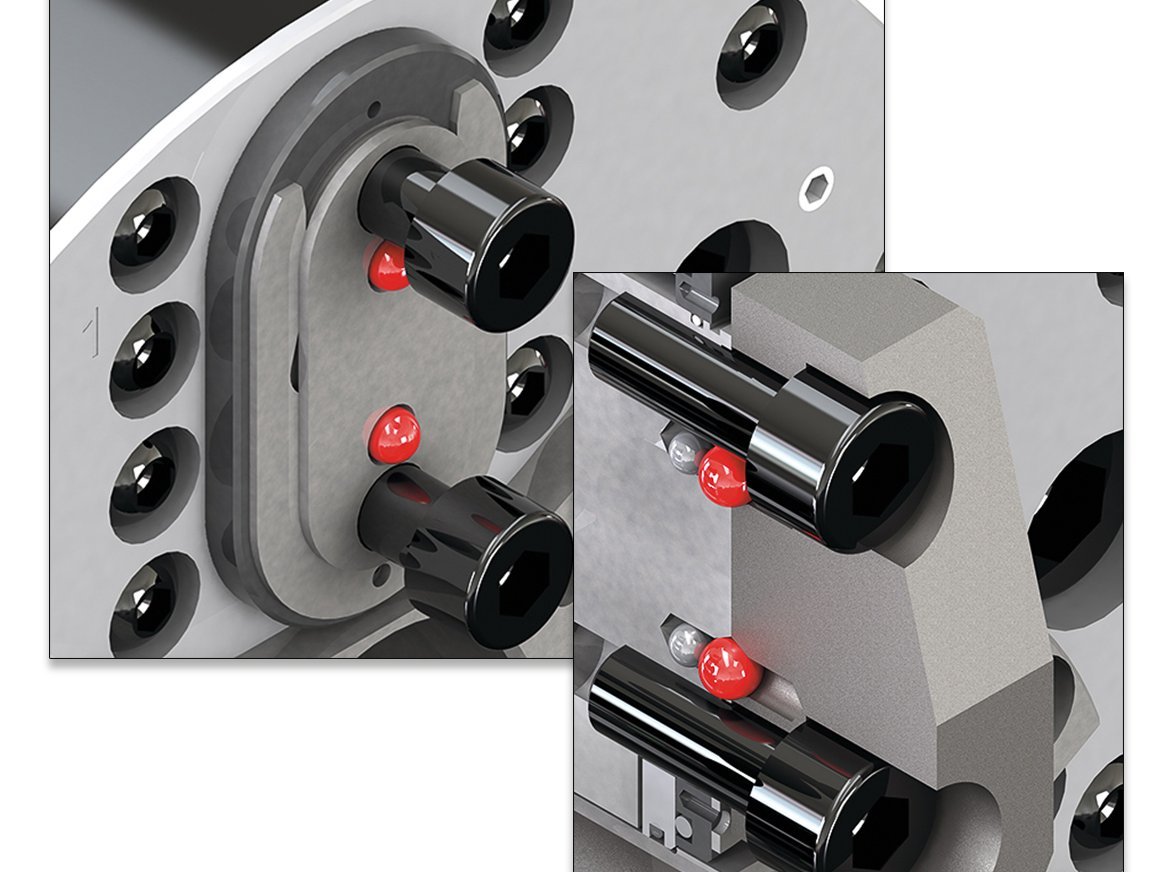

All power chucks of the Triton® generation feature precision jig-ground locating bores for precision ball positioning. This design feature ensures a quick clamping jaw change, independent of the chuck, without regrinding the jaws. Hence, this saves valuable time and increases productivity. Under optimal conditions, the jaws can be changed with an accuracy of ≤ 0.002 mm.

Highest precision even at high RPM

SwissChuck offers the Triton® with and without centrifugal force compensation. The optional, integrated centrifugal force compensation ensures constant clamping force even at high RPMs, especially for soft or hard turning. Due to its high precision and robust design, the Triton® can also be used for grinding applications, especially when grinding large and heavy components. Due to the low speeds during grinding, the Triton® is used without centrifugal force compensation.

TRITON®-PLUS 370

Outside clamping of transmission component

Operation:

Grinding or hard turning of the bore

Workpiece-specific accessories consisting of:

- Centerpoint insert

- Centerpoint

- Loading aid

- Top jaws with retraction function

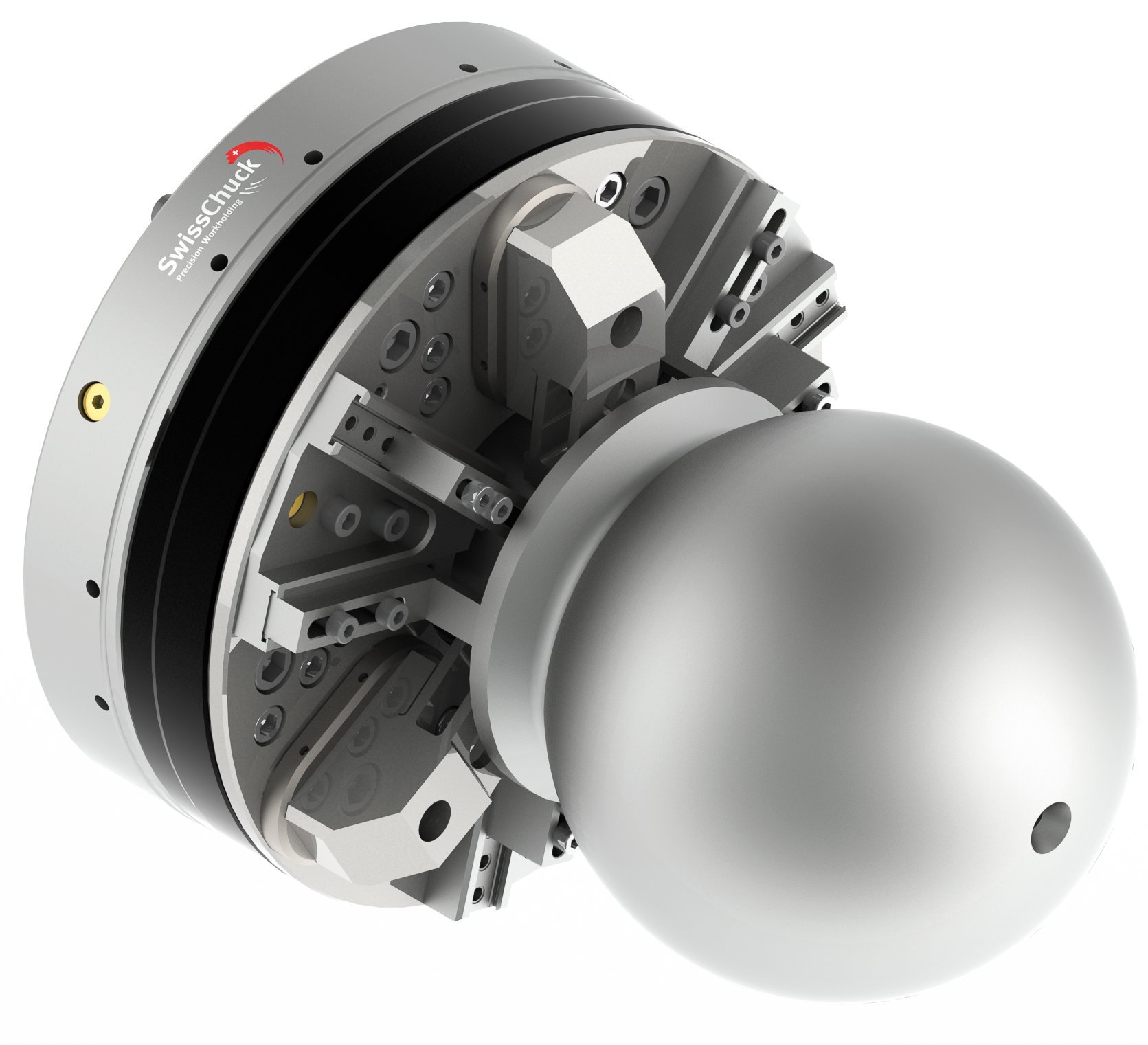

TRITON®-PLUS 370

External clamping of diverse ball heads

Operations:

Grinding of the ball form

Accessories consisting of:

- Hardened, ground in top jaws with retraction to axial end-stop

- Precision interface between base jaws and top jaws

- Radially adjustable axial end-stops

- Radially adjustable pre-centering as a loading aid:

TRITON®-PLUS 370

Clamping on the tip circle of a thin-walled gear part

Operation:

Grinding or hard turning of the bore

Workpiece-specific accessories consisting of:

- Compensating jaws for 6-point clamping

- Exchangeable top jaws to compensating jaws for different clamping diameters

- Precision interface between compensating jaws and top jaws

- Radially adjustable axial end-stops