Reduction of set-up time

Precision interfaces from SwissChuck - the set-up time killer

SwissChuck AG offers various technical solutions that make working on and with the machine more efficient. Different successive workpieces lead to repeated change-over times. Using suitable interfaces can reduce change-over times to a minimum, enabling more flexible production planning.

Positioning accuracy of ≤ 0.002 mm

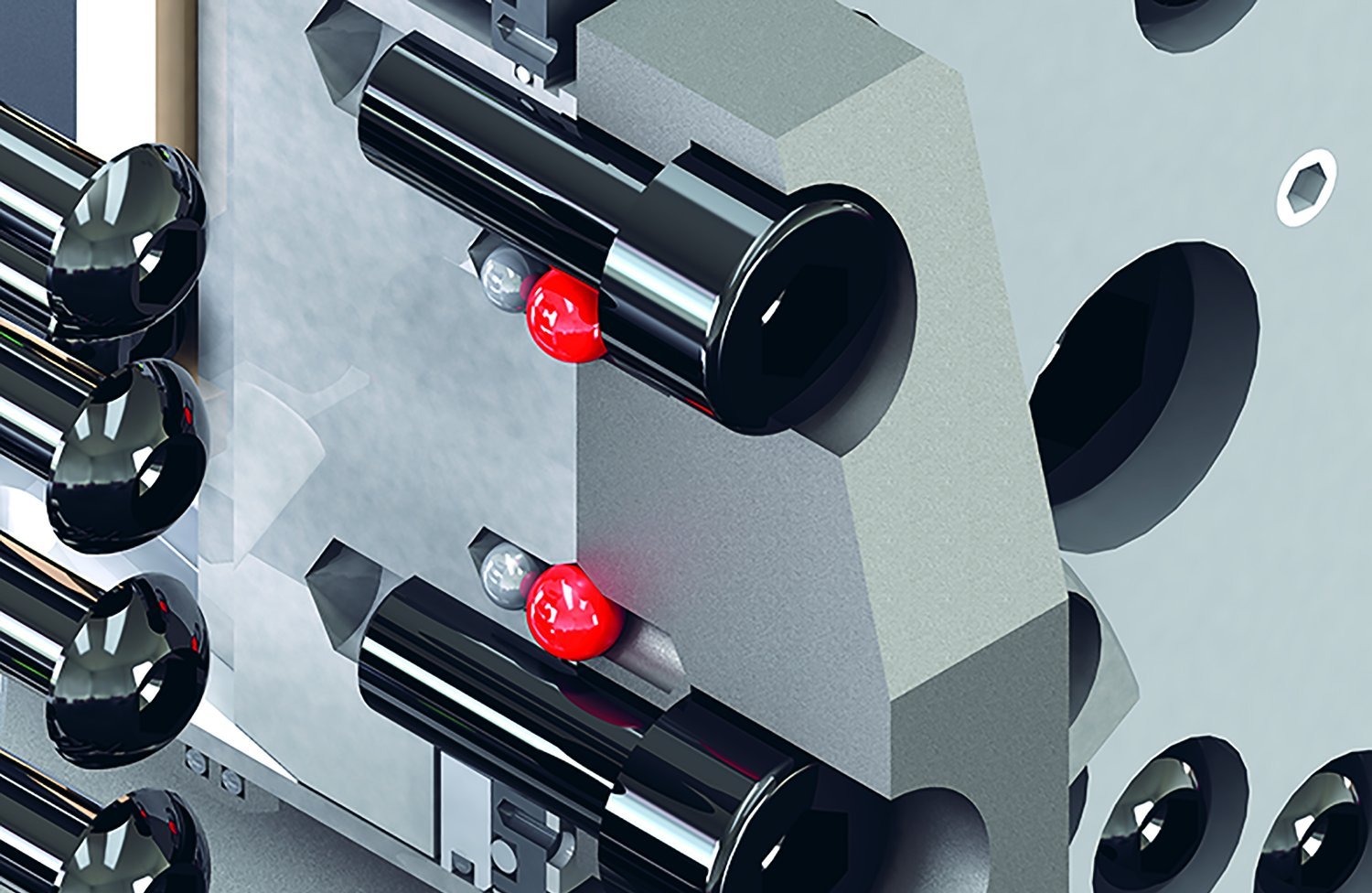

SwissChuck's centric power chucks feature precision jig-ground locating bores for precision ball positioning. This design feature ensures a quick clamping jaw change, independent of the chuck, without regrinding the jaws. Hence, this saves valuable time and increases productivity. Under optimal conditions, the jaws can be changed with an accuracy of ≤ 0.002 mm.

Precision interfaces from SwissChuck – Your added value

Workpiece-specific accessories

Reduction of setup time

Process optimization

Excellent quality

Save time during change-over

The following is a comparison between a jaw change-over on a precision chuck with and without precision ball positioning:

Without precision ball positioning

+ 10 min for mounting the jaws

+ 30 min for manual adjustment grinding of the jaws to the required accuracy

= 40 min until restart of production

With precision ball positioning

+ 10 min for mounting the jaws

+ 0 min manual adjustment grinding of the jaws (not required)

= 10 min until restart of production

- Time-saving up to 75% per change-over when using SwissChuck's precision ball positioning!

- For three different workpieces per day = 3 x 30 min = 90 min time saving per day