VMCHP

Precision diaphragm chuck with axial clamping

"Low deformation clamping in highest precision"

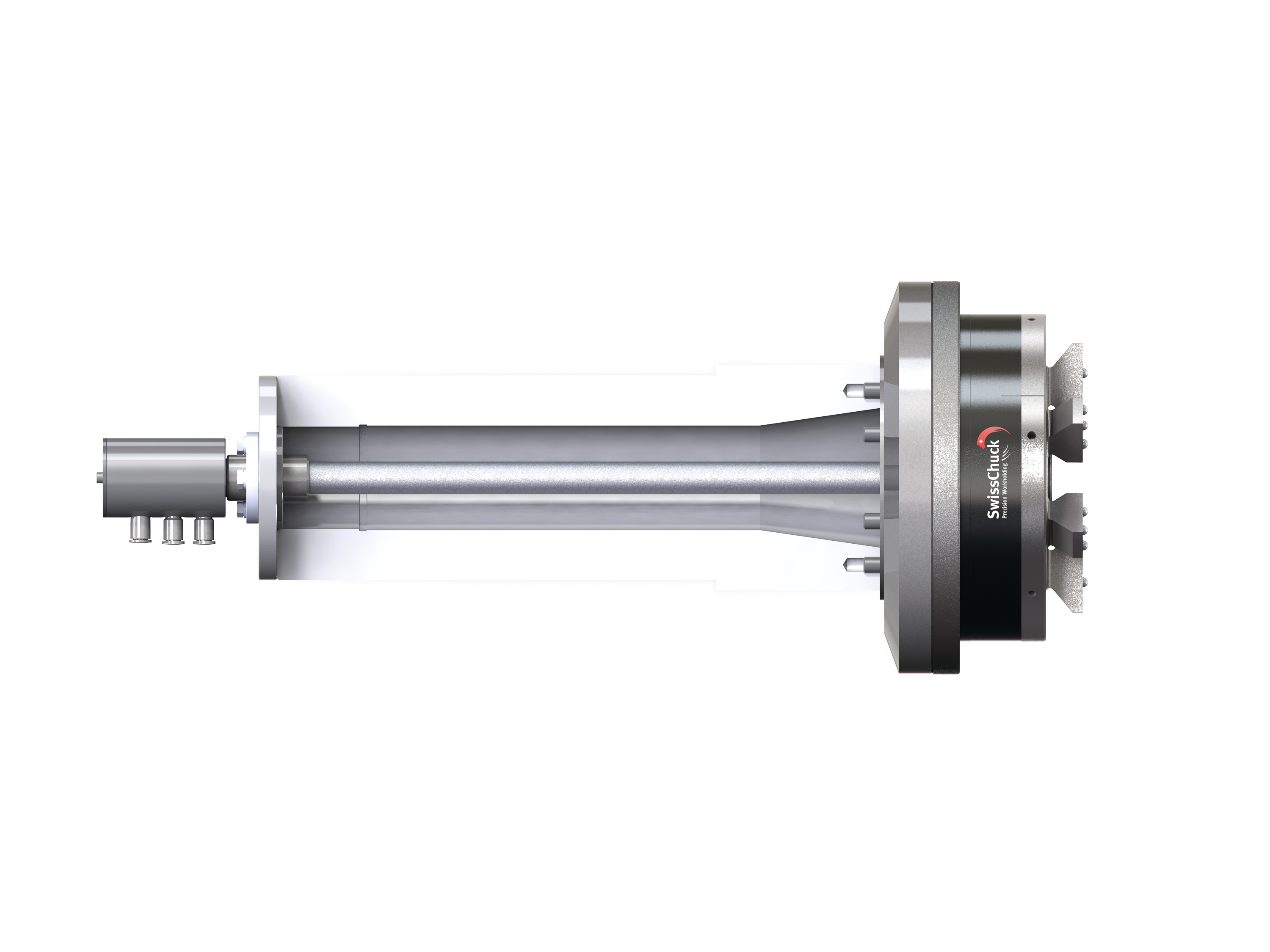

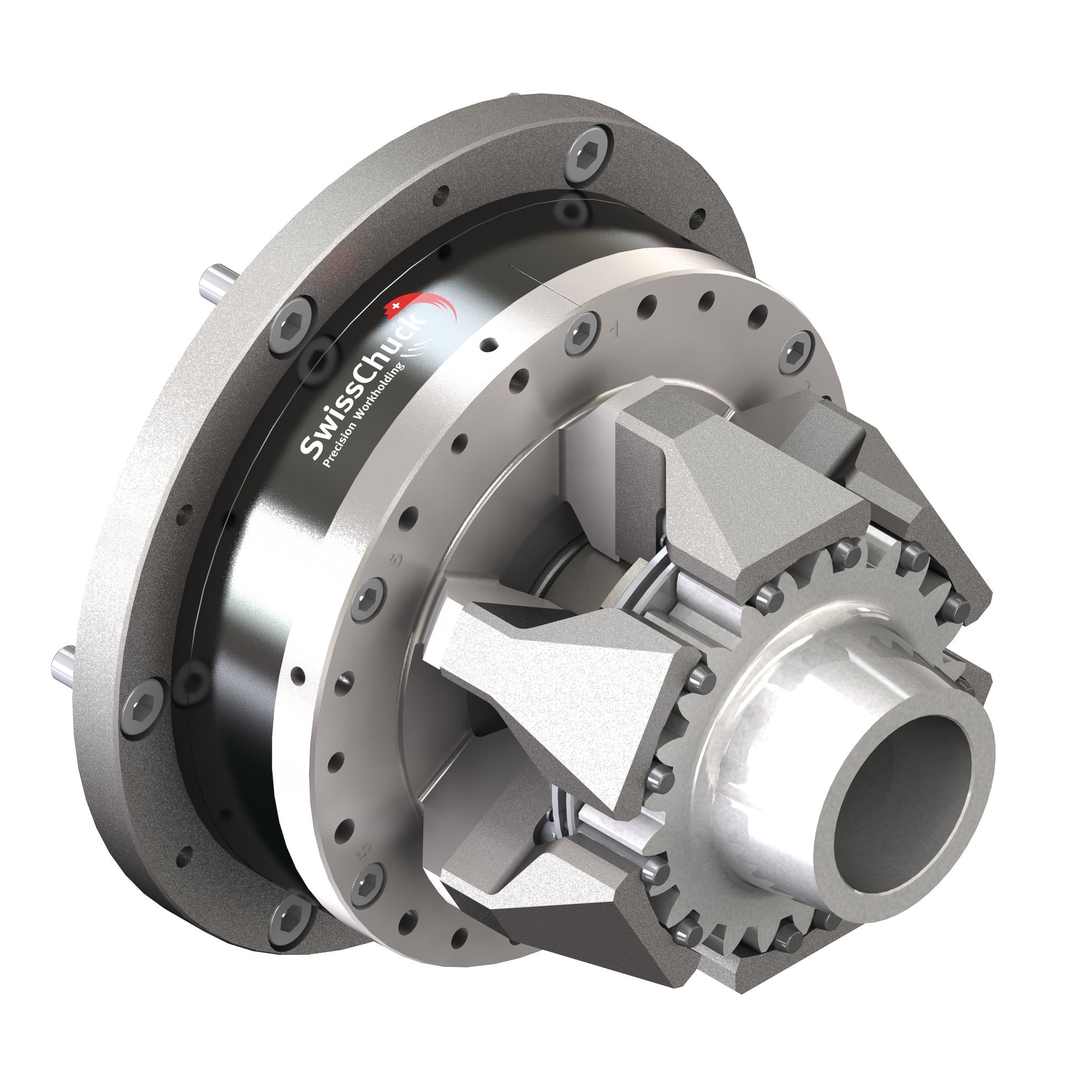

The pneumatic diaphragm chucks of the 6VMCHP series clamp workpieces at the highest precision. This chuck repeatably achieves a concentricity of ≤ 0.002 mm. Due to the force distribution over six jaws, plus the elasticity of the diaphragm, this chuck is particularly suitable for clamping low-deformation workpieces. The diaphragm chuck is operated via a rotary feed unit, which is screwed, through the machine spindle, directly into the chuck body.

In the center of the chuck is a through-hole, which can be used for direct grinding fluid supply, air purge operation, or workpiece presence recognition.

Technical Data

VMCHP

| Name | Item | ø Size (mm) | Hight (mm) | Max Speed (1/min) | Weight (kg) | Actuating max. (MPa) |

| 6VMCHP 85 | SX1007477 | 85 | 38 | 5000 | 2.2 | 6 |

| 6VMCHP 128 | SX1007621 | 128 | 58 | 3500 | 2.9 | 6 |

| 6VMCHP 160 | SX1007643 | 160 | 73 | 2250 | 4.9 | 6 |

| 6VMCHP 200 | SX1007661 | 200 | 91 | 1500 | 7.4 | 6 |

Functions & Fields of Application

- For external front-end actuation

- Pneumatically front-end actuated

- Sealed against contamination

- Ideal chuck for all cylindrical grinding machines

Advantages

- Highest precision ≤ 0.002mm

- Sufficient opening stroke enables automated loading

- Suitable for fast cycle times

- Axial end-stops are directly mounted on the chuck body, ensuring high stability

- Grinding fluid supply through the center

- Precision interface for top jaws; no regrinding of the clamping position

- Retraction effect to axial end-stop during clamping

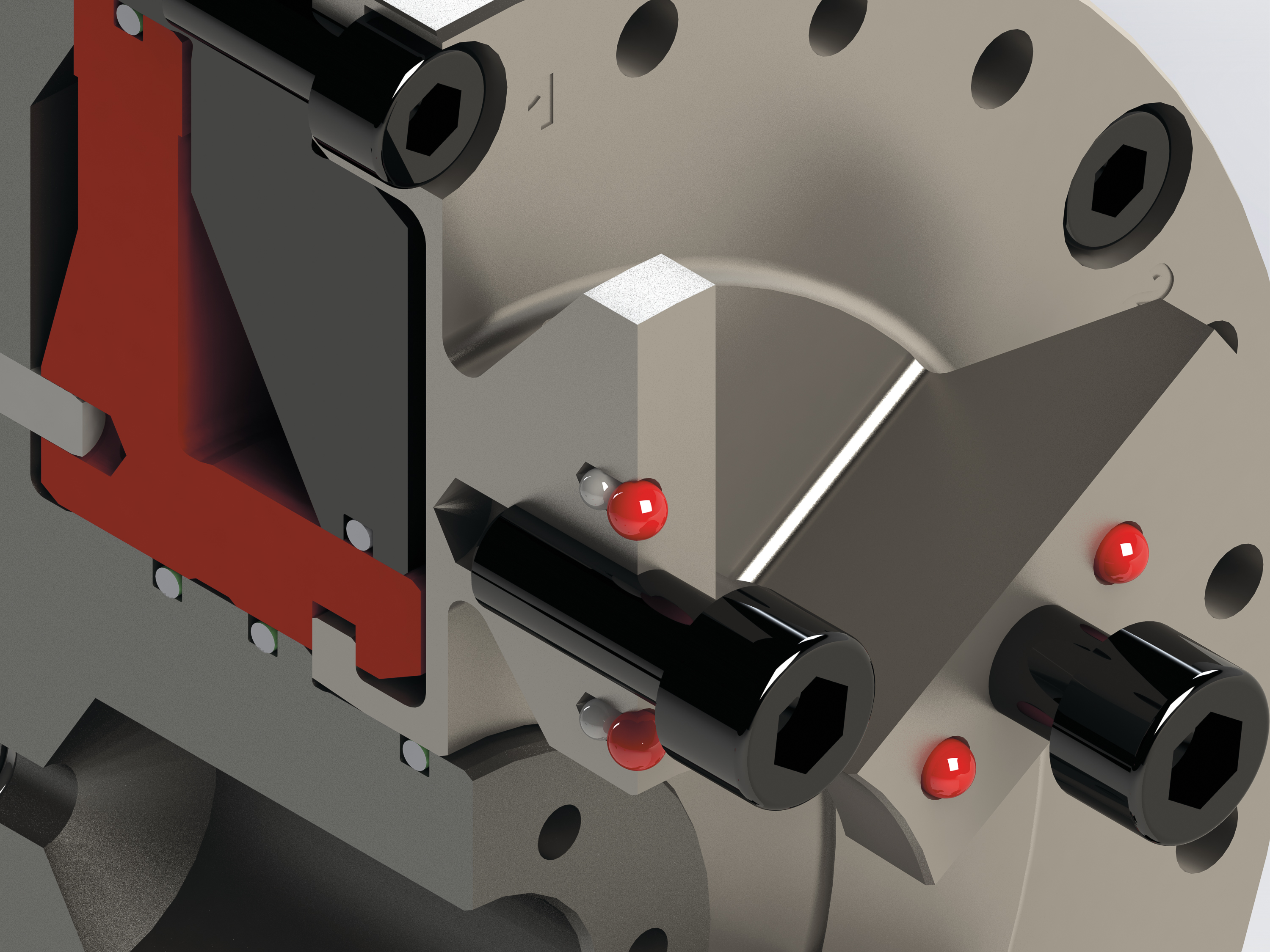

Changing jaws within micrometer tolerances is made easy!

All diaphragm chucks feature precision jig-ground locating bores for precision ball positioning. This design feature ensures a quick clamping jaw change, independent of the chuck, without regrinding the jaws. Hence, this saves valuable time and increases productivity. Under optimal conditions, the jaws can be changed with an accuracy of ≤ 0.002 mm.

Pull-back effect during clamping- ideal for workpieces with tight linear tolerances

Via the function of the membrane, the workpieces are pulled onto the axial end-stop during the clamping. This pull-back action ensures that thigh tolerances of linear dimensions are process-reliably maintained. Hence, this is particularly suitable for clamping workpieces that have their reference point on a specific locating surface. The forward position of the chuck body ensures the highest possible stiffness for axial end-stops.

6VMCHP 85

6VMCHP 85

Small workpiece ø7.5/3.5 x 5.8 mm:

- External clamping on ø3.5 with pull-back on axial end-stop

- Grinding of bore and faces

- Very tight linear tolerances, perfect pull-back to axial end-stop

- Grinding fluid supply through the center

6VMCHP 160

Spur gear:

Clamping on pitch circle with pull-back to axial end-top

- Grinding of taper and bore

- Highest concentricity to pitch circle

- Stable position on end-stop

6VMCHP 200

Form body:

Clamping on outside diameter

- Grinding of bore and taper

- Tightest tolerances in an axial direction

- Highest concentricity of the inside to the outside diameter

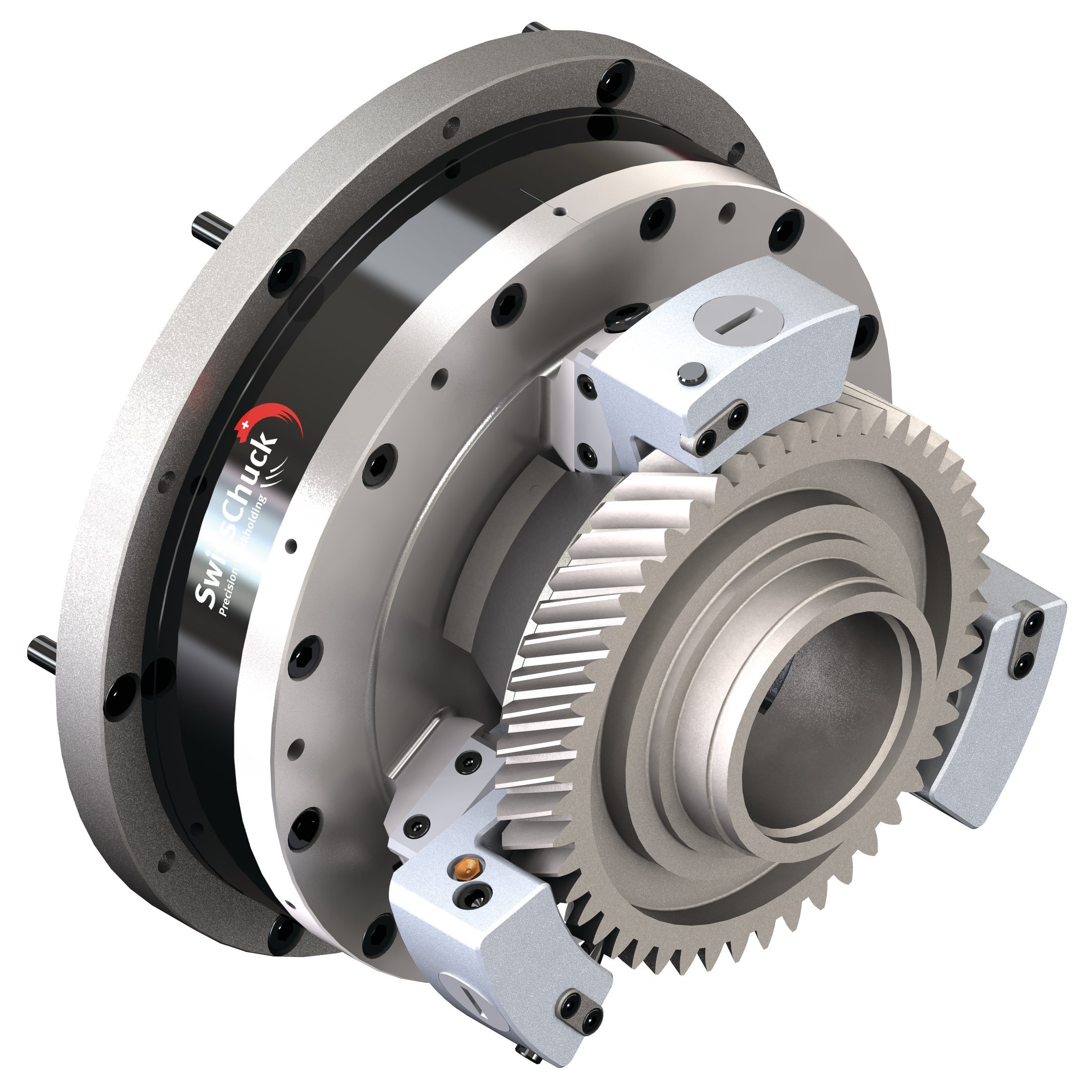

3VMCHP 240 Special Design

Helical gear:

Clamping on pitch circle with pull-back to axial end-top

- Grinding of bore and outside diameter

- Fast change-over of jaws, radially accessible mounting screws

- With pre-centering pins, radially adjustable

KFHP

Precision power chucks for large workpieces

KCHP / VKCHP

Precision power chuck for cylindrical grinding machines