Face drivers & counterpoints

Face drivers with matching spare parts and accessories

"The ideal solution for machining the complete outside contour of shaft-type workpieces."

The complete outer contour of the workpiece can be finished with one clamping operation and maximum torque transmission. NEIDLEIN face drivers are mechanical clamping systems equally suitable for soft and hard turning. We, as SwissChuck AG, have exclusive representation rights in Switzerland. Contact us for more information.

Overview of the different face drivers

Turning with a movable center point integrated into the face driver

FSB / SB & FSP / SP

Face drivers FSB/SB, and FSP/SP are power-operated on the tailstock side. The workpieces are clamped centrically utilizing a movable centering point, compensating for different centerings and thus ensuring a constant zero-point on the workpiece face.

The maximum concentricity deviation is approximately 0.02 mm.

The tailstock force should be in line with the chosen driving pins/washers to ensure maximum torque transmission.

As the general representative of Neidlein Spannzeuge GmbH in Switzerland, we will be pleased to help you.

Clamping system specifically designed for grinding

FFBR / FBSR

Face drivers FFBR/FBSR are power-operated on the spindle side and power-loaded on the tailstock side. The workpieces are clamped centrically utilizing a fixed center point, leading to high concentricity. The zero-point position is located in the workpiece center.

When loading and unloading the workpieces, the driving pins are retracted. Pivot-mounted driving elements compensate for any unevenness on the workpiece face. The face driver is cylindrically stepped on the head side to guarantee a possible clearance for the grinding wheels. The face driver can be finely adjusted for the highest concentricity requirements by setting screws. The maximum runout deviation is approximately 0.002 to 0.006 mm.

FFB / FFBH

Face drivers FFB/FFBH are power-operated on the spindle side and power-loaded on the tailstock side. The workpieces are clamped centrically utilizing a fixed center point, which leads to high concentricity. The zero-point reference position is in the workpiece center.

The maximum out-of-roundness is approximately 0.002 to 0.01 mm.

The tailstock force should be approximately 30% higher than the clamping cylinder force to ensure safe clamping.

As the general representative of Neidlein Spannzeuge GmbH in Switzerland, we will help you select the clamping device and determine the clamping forces.

Hard turning with a fixed center point integrated into the face driver for the highest accuracy

FFB / FFBH / FFP

Face drivers of types FFB/FFBH/FFP are power-operated on the spindle side and power-loaded on the tailstock side. The workpieces are clamped centrically utilizing a fixed center point, which leads to high concentricity. The zero-point reference position is in the workpiece center. The compensation of the driving pins is realized hydraulically on the FFB, FFBH, and FFP types. This design achieves the best possible concentricity results.

The maximum out-of-roundness is approximately 0.002 to 0.01 mm.

The tailstock force should be approx. 30% higher than the clamping cylinder force to ensure safe clamping.

As the general representative of Neidlein Spannzeuge GmbH in Switzerland, we will help you select the clamping device and determine the clamping forces.

Milling with a movable center point and fixed driver heads

FDNC

Type FDNC face drivers are power-operated on the tailstock side. The workpieces are centrically clamped utilizing a movable center point, compensating for different centering and thus ensuring a constant zero point on the workpiece face. Backlash-free workpiece driving is achieved using rigid driving heads. The adjustable spring-loaded center point ensures the stability and absorption of high lateral forces. The face driver can be finely adjusted for high concentricity requirements via setting screws. The maximum runout deviation is approx. 0.02 mm.

Functions & Fields of Application

Face drivers of types FFB/FFBH are power-operated on the spindle side and power-loaded on the tailstock side. The workpieces are clamped centrically utilizing a fixed center point, which results in high concentricity. The zero-point position is in the workpiece center. Originally designed for turning operations, the FFB/FFBH face driver is now widely used in grinding operations. Without retracting the driving pins and with the NEIDLEIN mounting Ø of 100 mm, the type FFB/FFBH are an alternative to the face drivers FFBR/FBSR, especially for large workpieces. The compensation of the driving pins is hydraulically governed for the type FFBH, leading to excellent concentricity.

The complete outer contour of the workpiece can be finished with one clamping operation and maximum torque transmission. NEIDLEIN face drivers are clamping systems equally suitable for grinding soft and hard workpieces.

Advantages

- High precision

- Machining of the complete outside contour in one clamping operation

- Low maintenance

- A complete package including mounting and live center point / dead center point on the side of the tailstock

- Economical alternative to conventional clamping tools

- Direct connection to spindle possible

- Individual connection to your machine is possible

- Compensating driver elements for FFBR / FBSR

- Extended service life of the driver elements and cutting tools due to vibration-free running

- FSB / SB)

- Compensating driver elements / optimal clamping of the workpiece (FSB /SB)

Machine the complete outside contour in one clamping operation

With face drivers from NEIDLEIN, you can achieve the highest concentricity accuracies - and in one clamping operation over the complete outer contour.

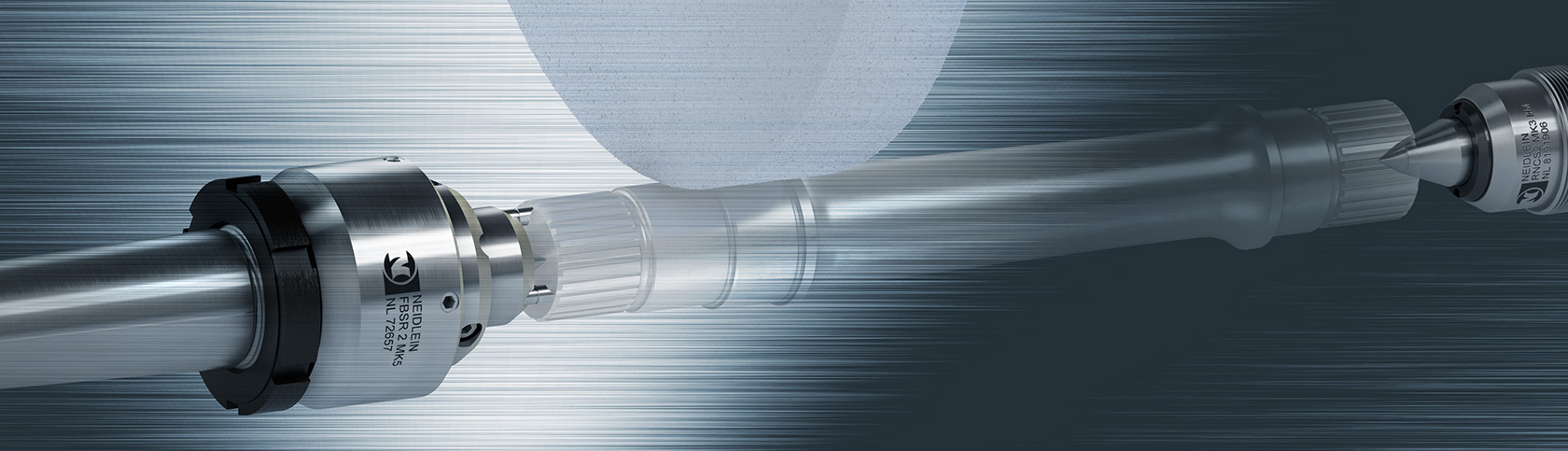

Face driver FBSR 2 MK5 for grinding

Transmission shaft

Grinding of the complete outside contour

- The complete grinding operation in one clamping operation is possible

- Face drivers are power-operated on the spindle side and power-loaded on the tailstock side

- The zero-point position is in the workpiece center

- The maximum runout deviation is approx. . 0.002 - 0.01 mm

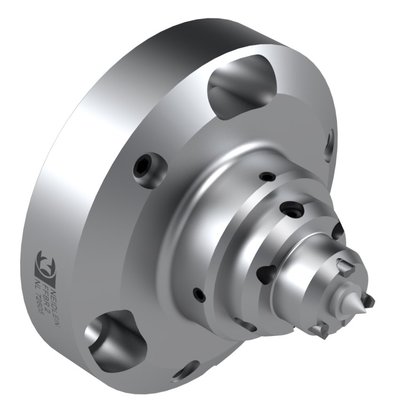

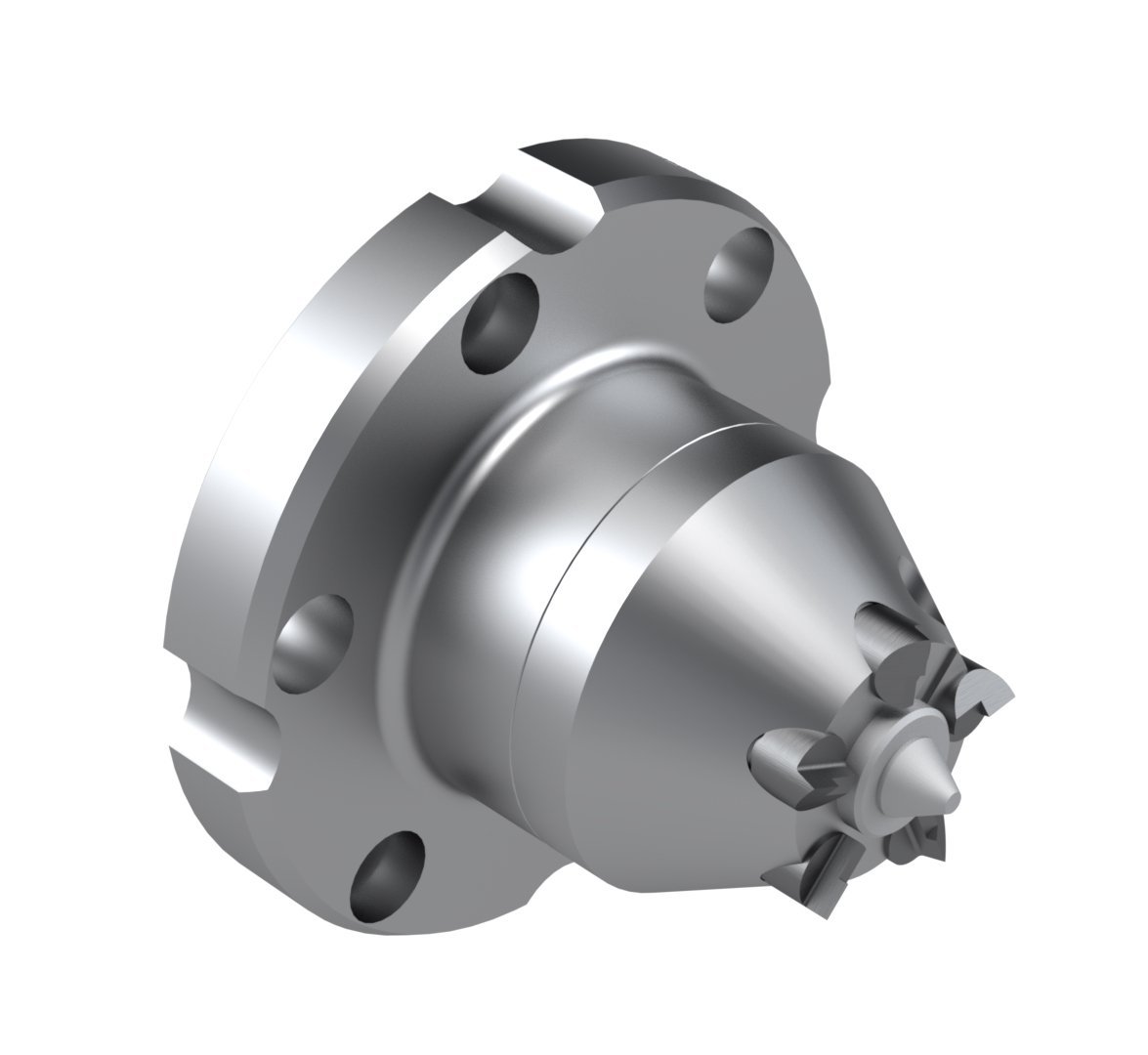

Face driver FFB 2 for hard turning

Turning the outside diameter of a bevel gear part:

Clamping via an FFB 2 face driver and live center on the tailstock side

- Turning the shaft diameter in one clamping operation

- Connection to the machine via a flange

- Maximum torque transmission leading to a high metal removal rate

- Compensating driver elements / optimum clamping of the workpiece

Face drivers & counterpoints

Face drivers with matching spare parts and accessories

PZLHM

Compressed air – Hollow clamping cylinders